This website has been automatically translated. Errors in translation are possible. On this reason we does not warrant for the guarantee for the correctness of the automatically Translation. The source and the valid Version is the german Version of this website.

We currently offer our standard silos in several sizes:

Single-chamber steel silo (double chamber available upon request)

for cement storage

Silo diameter: 2900

Cone height: approx. 60°

Outlet diameter: NW 300

Equipment for single-chamber silo:

Filling line inside or outside with flange

Cable routing inside or outside

Inspection opening in the silo roof

Filter frame for Silotop Zero Jet Filter

Crushing cone attached inside the outlet area

Water deflection ring outside the cone

Roof edge railing

Crane eyes on the silo roof and silo shell

Surface treatment: All silo exterior surfaces blasted to SA 2.5; 1 x primer coat approx. 60 µm;

1 x 2K top coat 40 µm RAL 9002; silo interior surfaces untreated, swept clean

Access ladder or transmissions bridge from silo roof to silo roof with railing, hot-dip galvanized

EX-Implo valve NW300,

Silo gate valve NW300 with hand lever

Electric silo level detection system for binding agents using microwave pulses guided on a steel cable

(radar on the cable)

SILOTOP polyplea filter D = 800 mm

Silo pressure detector

Silo overfill protection for one silo chamber

Air aeration system

Cable package for wiring all devices

Technical documentation consisting of an overview drawing, structural drawing, and transport drawing

....Or our low budget silos (manufactured in Romania)

in two sizes:

approx. 65m3/ 80to

Steel sheet silo (also available as a mobile version)

approx. 65m³, single-cell

for storing cement or similar products

Silo diameter: 2,900 mm

Total height including base: approx. 14,207 mm

Top railing to top floor

Outlet diameter: NW 300

Outlet height: approx. 1,980 mm

Silo support axis dimension: 2,050 mm

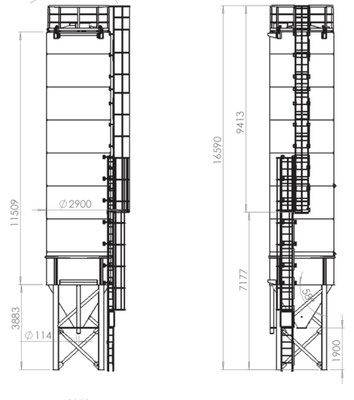

approx.80m3/ 100to

Steel sheet silo (also available as a mobile version)

approx. 80m³, single-cell

for storing cement or similar products

Silo diameter: 2,900 mm

Total height including base: approx. 16,590 mm

Top railing to top floor

Outlet diameter: NW 300

Outlet height: approx. 1,900 mm

Silo support axis dimension: 2,050 mm

Silo equipment and additional services:

(available at an additional cost) - Silo equipment (filters, valves, cement level, etc.) - Ladders or bridges - Mobile foundations - Delivery and installation

Equipment / Fittings, e.g., for 1 single-chamber mobile silo

-1 DN 100 internal filling line with flange

-1 DN 60 external cable conduit in the silo

-1 DN 600 inspection opening in the silo roof

-1 filter frame for Silotop Zero jet filter

-1 fixed internal crushing cone in the outlet area

-1 external water deflector ring on the cone

-1 roof edge railing

Ø 2,800 mm galvanized, H = 1,200 mm

-4 crane eyes on the silo shell

-2 extended crane eyes on the silo roof

-1 folding access ladder, approx. 15.00 m,

hot-dip galvanized with safety cage, one access step, and

a safety door at the ladder exit. Designed in accordance with accident prevention regulations (UVV)

Surface treatment of the silos:

All external silo surfaces are blast-corroded according to SA 2.5

1 x primer coat approx. 60 μm

1 x 2K top coat approx. 40 μm RAL 9002

Silo interior surfaces untreated, swept clean

Silo equipment

- 1 x jet filter Silotp Zero SILAB14EV

- 1 x continuous level probe type Vegaflex 82

- 1 x full indicator as a rotary paddle switch

- 1 x pressure detector

- 1 x overpressure/underpressure flap

- 1 x air aerator with 4 ventilation nozzles

- 1 x silo shut-off valve NW 300

- 1 x pinch valve with limit switch and Storz coupling

- 1 x maintenance unit for the pneumatics

- 1 x electrical control cabinet

including horn and flashing light

including electrical and pneumatic pre-assembly

up to the silo base

Mobile foundation inserts

Welding assemblies and individual parts as inserts

to On-site grouting of the mobile foundations

2 x 2.00 x 4.00 m

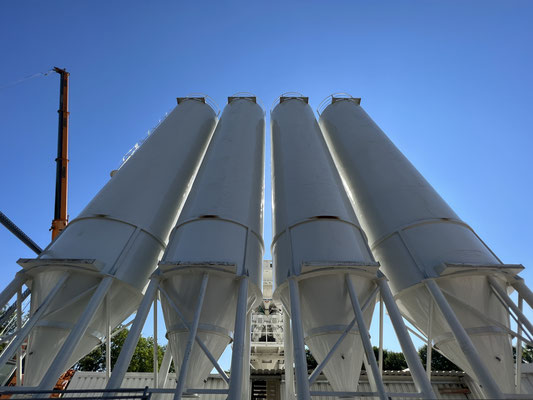

pictures 65m3/80to Silos

pictures 80m3/100to Silos

Have we piqued your interest? Send us your inquiry now using our inquiry form!

WIR SIND FÜR SIE DA

Sie haben eine Frage oder möchten sich persönlich beraten lassen? +49 (0) 3904 4989 553

Montag bis Freitag von 10 – 16 Uhr

oder nutzen Sie unser Kontaktformular.

Ihre Vorteile

- von der Planung bis zur Inbetriebnahme

- mit über 20jähriger Erfahrung

- alles aus einer Hand

- Individuelle Beratung, schnelle Lieferung und Rundum-Service

- europäische Markenprodukte und Komponenten

- schnelle Lieferung

- professioneller Aufbau & Inbetriebnahme

- Restbetonanlagen & Silos MADE IN GERMANY